Introduction

Context

The automotive industry is of strategic importance to the European economy and its products and services impact the life of European citizens on a daily basis. The sector represents around 12 million direct and indirect jobs and delivers a sizeable positive contribution to the EU trade balance (growing over the last few years and reaching € 90 billion in 2011). The industry records the biggest private spending on research and innovation (€ 28 billion in 2009) and is an essential driver for technological innovation. It is an important multiplier of growth, due to strong economic linkages with many industrial sectors.

The automotive sector is at a historic turning point in the coming decade. First of all, production and trade patterns are shifting. While the European market is considered mature, several third markets are growing fast, changing the trade flows and the automotive value chain. The intense competitive pressure is growing further and EU companies are increasingly being challenged in their home market, while developing opportunities in third markets. Secondly, the climate agenda becomes more urgent and even more is expected from technological progress. To meet long-term greenhouse gas emissions targets as well as air quality objectives, the internal combustion engine needs to be further improved, being accompanied by the development and progressive implementation of breakthrough technologies, such as electrified propulsion. Read more

Vision & Objectives

Various technologies will be advanced to TRL 6 or TRL 7 and integrated in two demonstration vehicles such as fuel-efficient engine combustion, charging, EGR, thermal management concepts and exhaust gas treatment concepts. A full calibration and assessment of the vehicles and underlying technologies will take place to proof real driving emissions below upcoming Euro 6 limits, a substantial reduction of the emitted particulate number including sub 23nm particles and a more than 5% improved overall fuel efficiency. An even higher efficiency improvement is pursued with a combustion system with a variable compression ratio, however, the VCR will not be integrated to the demonstrator vehicles.

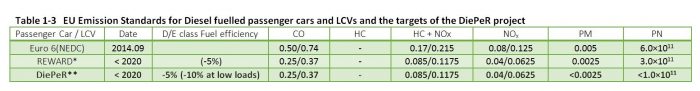

DiePeR’s targets reflecting the project’s ambition to “reduce the emission of nanoparticles with down to 10 nm in size compared to best in class 2015 equivalent vehicles under Real Driving conditions” are presented in the last row of Table 1-3.

* The REWARD project aims to go beyond Euro 6 limits including real driving conditions with a conformity factor of 1.5.

** DiePeR goes beyond the targets of REWARD, i.e. ≥ 5 % (10% in low load area!) improved fuel efficiency compared to best in class 2015 equivalent size and torque engines of the participating OEMs on the market and real driving emissions (RDE) that go beyond EU 6 (NEDC), i.e. ≥ 50 % lower pollutants respectively and ≥ 80 % lower PN including particle emissions down to 10 nm in size. The PN limit will be reached with an efficiency curve of 50% at 10nm (of the measuring device). For real driving conditions a conformity factor of 1.5 is considered. Read more: objectives